When you purchase through links on our site , we may earn an affiliate commission . Here ’s how it work .

Scientists have usedartificial intelligence(AI ) to plan never - before - ascertain nanomaterials with the strength of C steel and the lightness of styrofoam .

The new nanomaterials , made using machine learnedness and a 3D printer , more than double the strength of subsist designs . The scientist behind the raw work say they could be used in strong , light and more fuel - efficient element for airplanes and car . They published their finding Jan. 23 in the journalAdvanced material .

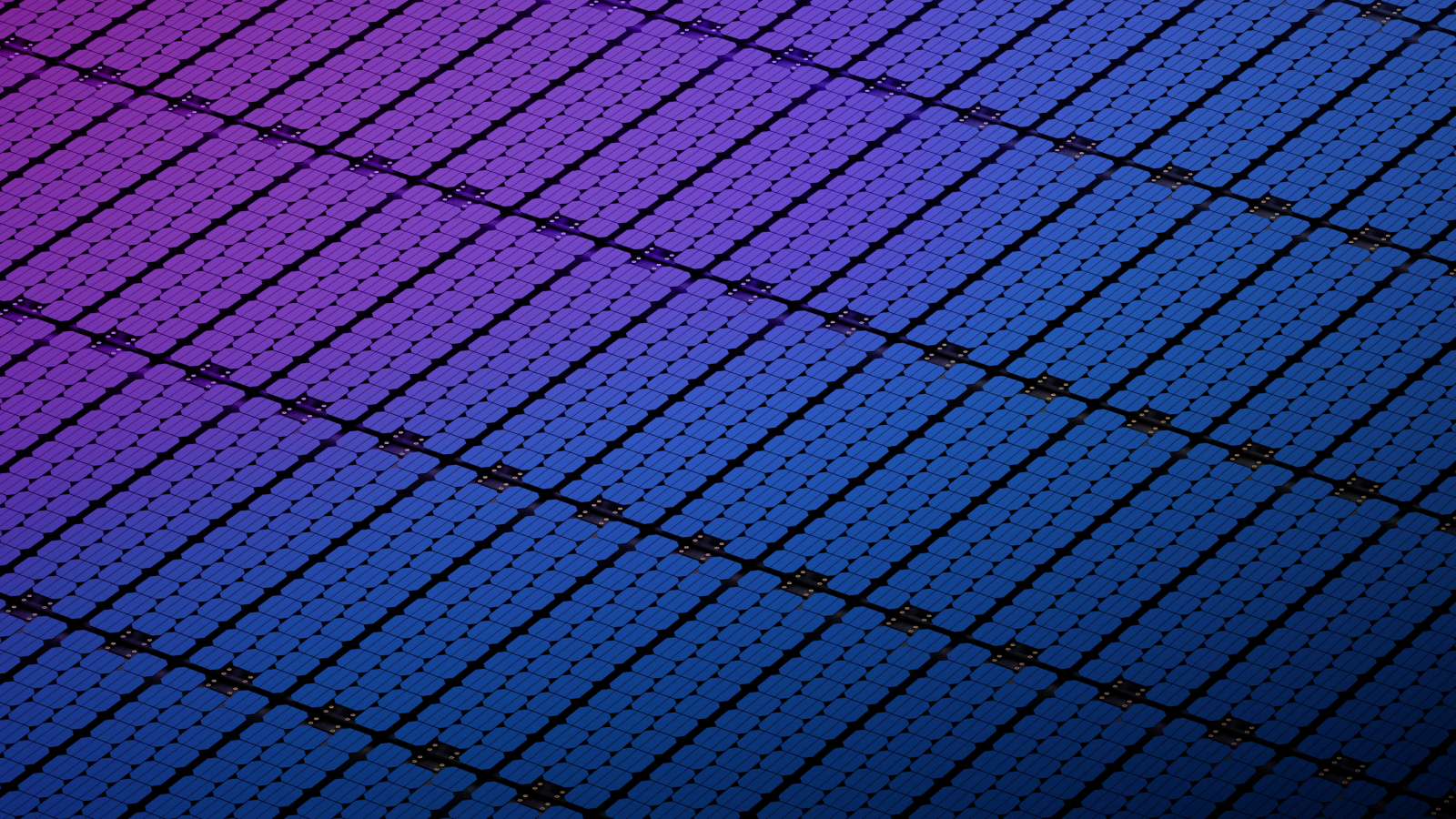

An image of the new nanomaterial.

" We trust that these young material designs will finally lead to ultra - light weight component part in aerospace applications programme , such as planer , helicopter and spacecraft that can reduce fuel need during flight while maintaining condom and performance , " co - authorTobin Filleter , a professor of engine room at the University of Toronto , said in a affirmation . " This can ultimately help reduce the high atomic number 6 step of flying . "

In many material , strength and formidability can often be at odds . Take a ceramic dinner plate , for example : while plates are usually strong and can have a bun in the oven heavy loads , their effectiveness come at the price of toughness — it does n’t take much free energy to make them shatter .

Related : scientist expose revolutionary method acting that make fuel from water supply and sunlight — but it ’s not eat up yet

The same problem enforce to nano - architectured materials , whose construction from multitudes of diminutive , repeating building blocks 1/100th the thickness of a human pilus makes them impregnable and soaked for their weight unit , but can also cause strain concentrations that head to sudden breakage . So far , this tendency to shatter has throttle the materials ' applications .

" As I conceive about this challenge , I substantiate that it is a perfect problem for motorcar learnedness to tackle , " first - authorPeter Serles , an engineering research worker at Caltech , said in the statement .

To search for better ways to plan nanomaterials , the investigator simulated possible geometry for their design before pass them through a machine learning algorithm . By learning from the designs they had generated , the algorithm was able to predict the best shapes that would evenly distribute hold stress while also carrying a fleshy loading .

— Inside the 20 - year seeking to untangle the bizarre realm of ' quantum superchemistry '

— scientist just beat 1 step closer to creating a ' superheavy ' ingredient that is so boastful , it will add a new quarrel to the periodic mesa

— chemist broke a 100 - year - erstwhile rule to make passing unstable molecules

With these embodiment in bridge player , the researchers used a 3D printer to make their new nanolattices , finding that they could stand firm a accent of 2.03 megapascals for every cubic cadence per kilo — a strength five times higher than atomic number 22 .

" This is the first time machine learning has been applied to optimize nano - architected materials , and we were shock by the improvement , " Serles state . " It did n’t just replicate successful geometry from the training datum ; it learned from what changes to the shapes worked and what did n’t , enable it to predict entirely new wicket geometry . "

The researchers said their next steps will center on surmount up the cloth until they can be used to make bigger portion , while also search for even undecomposed designs using their process . The primary aim is to design much lighter and stronger components for vehicles in the hereafter .

" For example , if you were to supervene upon components made of titanium on a plane with this material , you would be look at fuel savings of 80 liter per year for every kilogram of material you replace , " Serles said .

You must confirm your public display name before commenting

Please logout and then login again , you will then be prompt to come in your display name .